The center, which started to be established in 2020 with a fund of 6 million 250 thousand liras provided within the scope of the "Attraction Centers Support Program" of the Ministry of Industry and Technology, became operational within the body of SBTU.

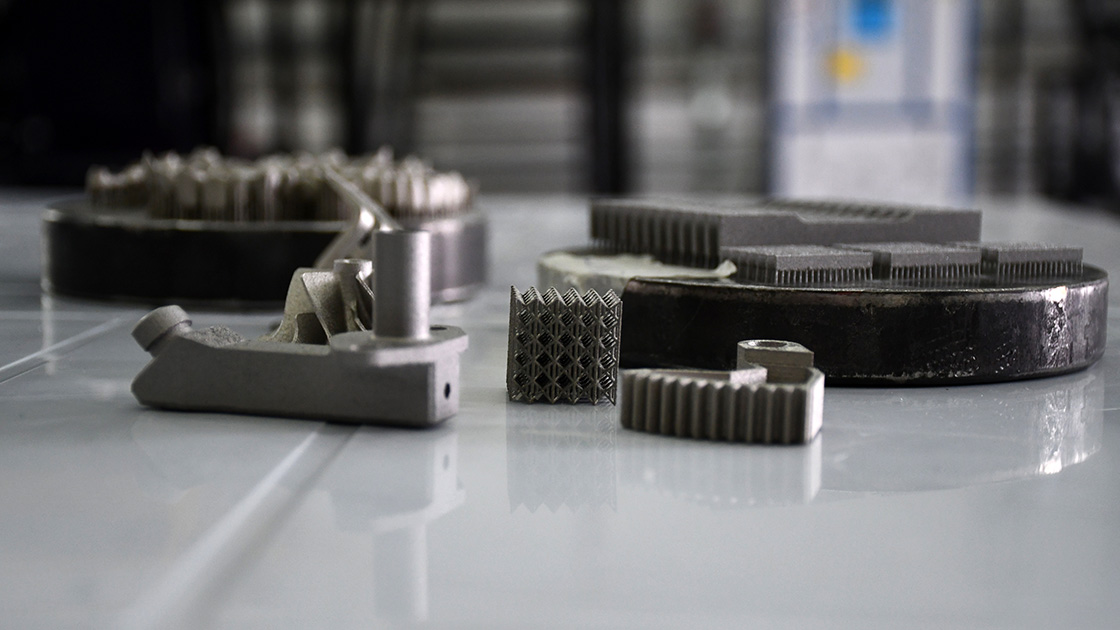

The production of titanium, iron, boron, nickel and cobalt-based alloys in solid forms and metal powders, which are needed by the aviation industry and the medical industry, was successfully carried out at the center in the Sivas Organized Industrial Zone.

SBTU Rector Prof. Dr. Mehmet Kul told Anadolu Agency (AA) that they are a university trying to specialize, especially in the defense industry.

Explaining that they learned that one of the most important problems of additive manufacturing is powder metal during the meetings with defense companies during the field visits, Kul said, "Both the high price of this product and the dependence on foreign countries were stated as a big problem. We applied to the Program and started working on our project after a funding of 6 million 250 thousand liras was provided in 2020." said.

2 ton order offer received while in trial production

Stating that they got very high quality results from their trial productions, Kul said, "They were very excited when the products obtained were shared with the private sectors. In fact, a businessman came from Istanbul and stated that he wanted to place the 2-ton order immediately. Our work on this continues. Also, not only in the defense industry, but also in the medical industry. Additive manufacturing is used. In other words, the raw materials needed by the medical industry will also be produced here. In addition, exports will be realized through these companies." he said.

Pointing out that they are also planning to work with TUSAŞ Motor Sanayii AŞ (TEI), an international manufacturer and design center that provides high quality products and services to the aviation industry, within the body of Turkish Aerospace Industries (TUSAŞ), Kul noted:

"We continue to work with TEI, one of the favorite defense organizations of our country, working on the engines of aircraft, helicopters and unmanned aerial vehicles, to realize the parts of these engines with domestic alloys and metal powders that we produce. Today, we received good news from there. The microscopic photograph of the products excited them as well. TEI , wants to work with us on titanium alloys in the field of aviation. We will realize this project with a study conducted through TÜBİTAK."

"1 kilogram is about 450 euros"

Emphasizing that the advanced alloys production center will also provide significant income to the university, Kul said, "Universities must now create their own resources. It is necessary to get out of resources that are only funded by the funds provided by the state. This facility was also established for this purpose. It will bring income to the university. "For example, 1 kilogram of this metal powder produced is approximately 450 euros. The devices in the facility have a capacity of 25 kilograms. Therefore, we have a production capacity that will provide high added value every time." used the phrases.

AA